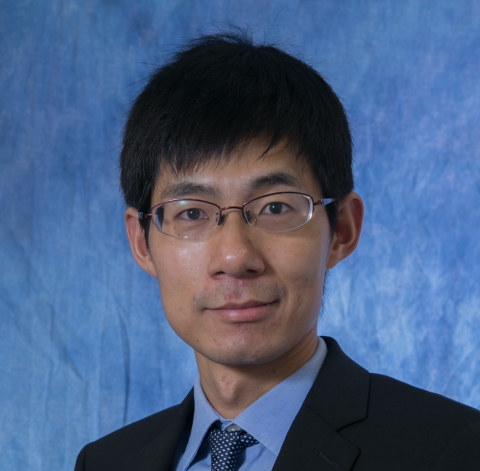

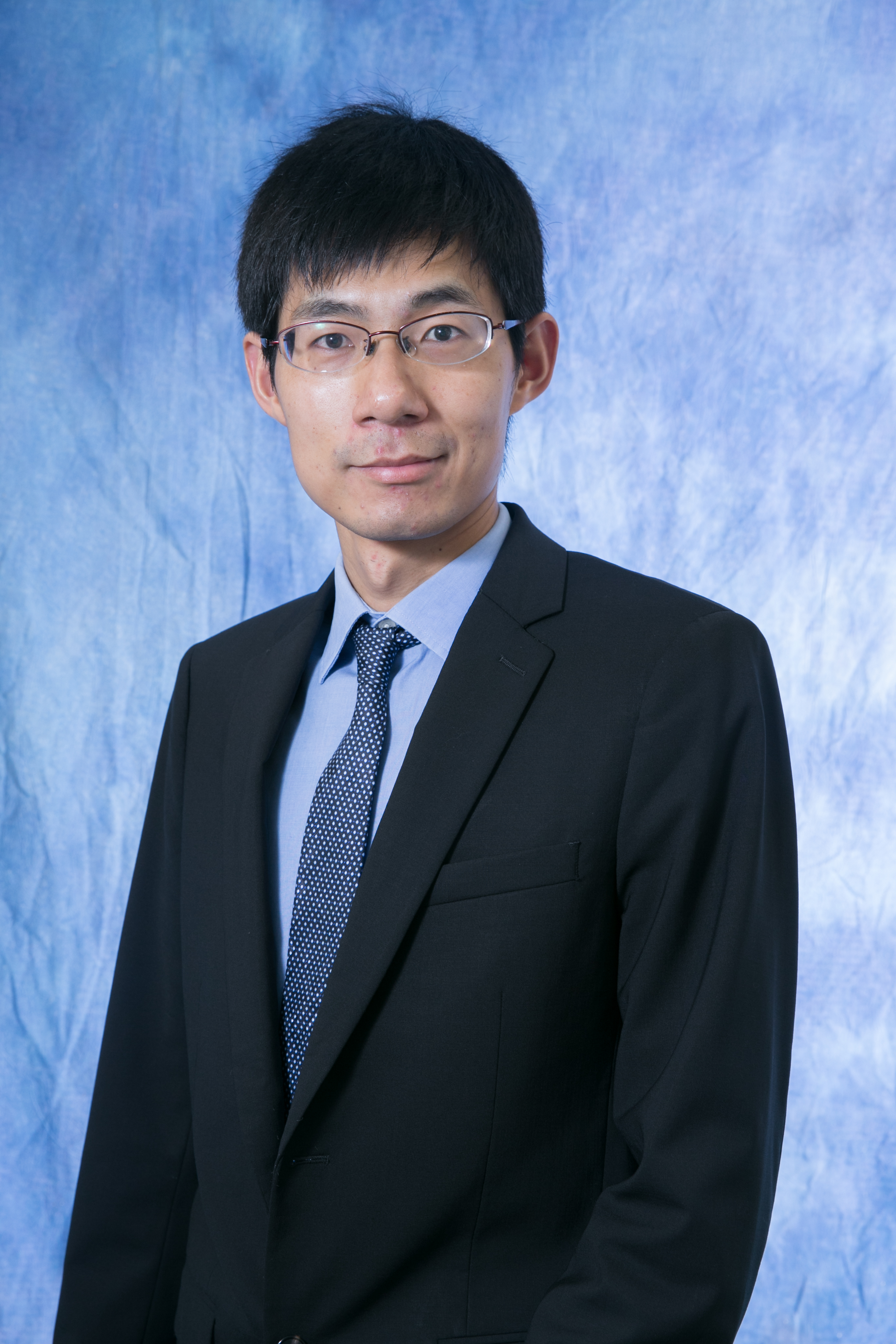

A research project led by Professor Zhou Renjie, Associate Professor, Department of Biomedical Engineering was awarded the 2023/24 Research Impact Fund (RIF) by the Research Grants Council (RGC). The project title is “Quantitative Phase Imaging Promoting Cell Biology, Biomedicine, New Materials and Beyond”. The Research Impact Fund was launched in 2017 to encourage local universities to conduct more impactful research and collaborate with stakeholders outside academia. It offers maximum grants of $10 million to each successful project, with the university or other partner providing the remaining 30% of the project cost. The duration of each project must be three to five years. About the project: Quantitative phase microscopy (QPM) is an emerging optical imaging technique for label-free, high-resolution imaging of living cells and other tiny substances. In QPM, the wavefront or phase delay of a specimen is mapped so that it can be used to infer the specimen’s shape, internal structures, material composition and so on. This novel microscopy technology allows for monitoring of intracellular dynamics and their responses to different treatments without harming the cells. Other advantages of QPM include high-precision, high throughput measurement capabilities that can potentially facilitate quality control during advanced manufacturing, especially chip manufacturing at the atomic scale. However, the precision of current QPM systems is limited, and they are difficult to operate and expensive, limiting access to them and their ability to make a profound impact. The research team is committed to developing novel high-performance QPM systems and demonstrating their broad application. With the aim of commercializing QPM technologies, they will cooperate with industry to add custom functions to their QPM systems, making them easy to use and cost-effective for user-specific applications. The team will also disseminate knowledge to the scientific and industrial communities so the technologies can be more widely applied. |

|